As project schedules become increasingly shorter and budgets become tighter, more contractors have turned to prefabrication to give their company a competitive advantage in the marketplace. According to a survey conducted in January 2020 by construction.com*, 62% of respondents have taken advantage of single-trade assembly prefabrication in the last three years and it’s easy to see why. In addition to saving precious time in the schedule and reducing labor costs, prefab improves productivity on the job site by requiring less material handling by installers, consolidating delivery of material to a single delivery vs. numerous deliveries for parts (improving the supply chain reliability), improving quality control and reducing scrap/waste on site.

With more and more companies boasting prefab capabilities it’s important to work with a prefab provider that will keep your interests at the forefront. At the Morse Group, we recognize that prefab is not the right solution for every project. We evaluate each individual project in detail to determine feasibility based on the project schedule and key milestones. We only utilize prefab when it presents significant, justifiable savings to the customer.

The Morse Group began using prefab in 1994 at regional automotive manufacturing facilities in order to meet tight installation schedules on complex projects. We began by prefabricating components such as terminal boxes, wire assemblies, operator stations and QAS system supports. We quickly learned that prefab was a game changer in terms of schedule management and on-site installation time. Over the years we’ve continued to learn and grow with each project and we bring the culmination of that experience to all new projects we work on. We’ve invested in our people ensuring they have the tools, knowledge and capability to provide cutting edge prefab opportunities. Our prefab team embraces collaboration and consistently challenges each other to never settle for the status quo. While our team has identified 100’s of prefab opportunities that include conduit, hangers, outlet assemblies, VFD racks, pre-punched panel tubs and junction boxes and even entire electrical rooms, we consistently strive to think outside the box to provide new, innovative solutions for our customer’s prefab needs.

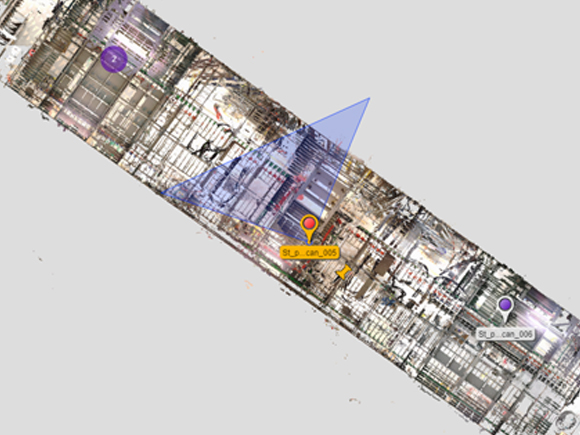

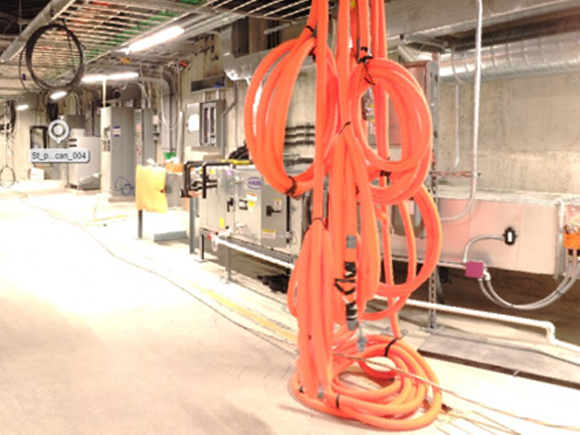

Our prefab team has the experience and expertise to generate prefab assemblies from both coordinated and non-coordinated projects. On coordinated projects, the prefab team takes advantage of BIM technology to get a clear view of the building layout and determine potential conflicts between trades before it impacts the schedule and results in costly corrections. From BIM, we can easily generate installation sheets and provide schedules for all content that is modeled. Non-coordinated projects require a slightly different approach to prefab. As a team, we review the project in detail and assist in identifying opportunities that make sense, save time and reduce project costs. Then, we laser scan the existing conditions to create a 3D model. This allows us to generate installation sheets like those used in a coordinated project. The prefabrication manager uses the information generated by the BIM model or the laser scans to quantify the material needed for purchase, place the order and prepare for assembly in our in-house prefabrication facility.

Our in-house prefabrication facility truly differentiates The Morse Group from our competitors and allows us to offer complete turnkey solutions to prefab. We have up to 150,000 sq. ft. of space available for prefab in-house. If there are any questions regarding an assembly, the designer is on-site to quickly provide an answer and keep the project moving along.

Once prefab assemblies are completed, they are kitted, labeled by specific project location and stored until needed on the job site. At which time the material will be delivered to the exact location it will be installed on-site. Each kitted cart includes a prefab installation drawing that serves as installation instructions. This delivery method reduces on-site waste from packaging debris, avoids clutter on the job site, reduces installation time and allows crews to be more efficient and productive.

The Morse Group has invested in our people, our processes and our facilities to perfect our approach to prefabrication. From opportunity generation to assembly, execution and installation, our team of experts has you covered. Next time you’re in need of prefab solutions, turn to a company that incorporates a collaborate team approach to prefab and will always keep your interests at the forefront of everything we do. Turn to the experts at The Morse Group!