Smart Automation & Visualization Technology

Driving Manufacturing Processes Forward

ASA incorporates smart automation and visualization technology to manual practices to help traditional manufacturers move into the 21st century. Our software captures, stores, and analyzes data from the factory floor in real-time and outputs the data in a manageable, easy-to-understand format that enables department heads, supervisors, and operators to make faster, more confident production decisions.

The Benefits of Smart Automation & Visualization

The key benefit of incorporating smart automation and visualization technology is the ability to make immediate production decisions based on accurate, real-time data from the manufacturing floor. With access to current and forecasted production values, management can make adjustments on the fly, reallocate resources, and identify bottlenecks. Another benefit of incorporating this technology is predictive maintenance. Interconnected sensors, actuators, and other devices are networked with computers for industrial applications allowing the system to monitor manufacturing performance over time and use the information gathered to predict future reliability. These predications allow for a machine or system to be serviced before an anticipated failure, when it is more convenient, and avoids costly downtime and work stoppage.

Other advantages of Smart Automation & Visualization Include:

Improved production line efficiencies to maximize throughput and decrease labor costs

Standardized quality and the development of a birth history

Shortened overall build times

Increased profit margins

Improved supply chain logistics

Improved inventory tracking and planning

Better customer experiences

Prevention of bottlenecks

Full project support

DESIGNING SOFTWARE TO MEET YOUR UNIQUE NEEDS

Our experienced and flexible software design engineers have the knowledge and expertise to work across multiple software platforms to create a custom visualization system to meet your unique manufacturing needs. Our team develops applications that incorporate all aspects of your business into one cohesive network allowing you to extract valuable data from the manufacturing floor.

Our Software Application Development Includes:

- Scheduling/production software integration

- Batch/recipe development and management

- Overall Equipment Efficiency Tracking (OEE)

- Data collection, machine learning and decision making

- Fault detection, logging, reporting and annunciation

- MES/MIS integration

- Aggregation, processing and reporting of data

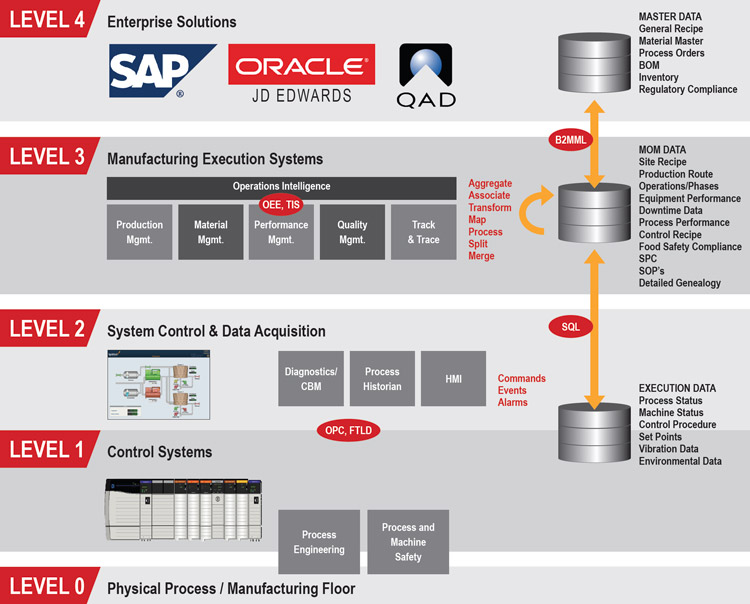

Determining Industry 4.0 Readiness

To start, we will need to determine your Industry 4.0 Readiness and decide what level of automation is the best fit for your company. Smart automation and visualization is not a one-size-fits-all solution for manufacturers. While some companies might need to implement level 4 process models to fully integrate their production facility with order scheduling, material use and nationwide logistics, other companies can benefit significantly by incorporating level 2 process models in order to gather valuable data and system status from the manufacturing floor. Our team is prepared to discuss your specific processes to identify where we can add value through smart automation and visualization.

Industry 4.0 Readiness Checklists

Do you know what questions you should be asking yourself when it comes to choosing the right technology? At ASA, we have developed a series of questions regarding data readiness, process management, security, governance, and organization to better prepare you for your needs.

Get The Checklist

Are you ready to find the right partner for your automation needs? Let us know how we can help!