Mercury Marine V12 Verado Assembly Line

Fond du Lac, WI

Project Overview:

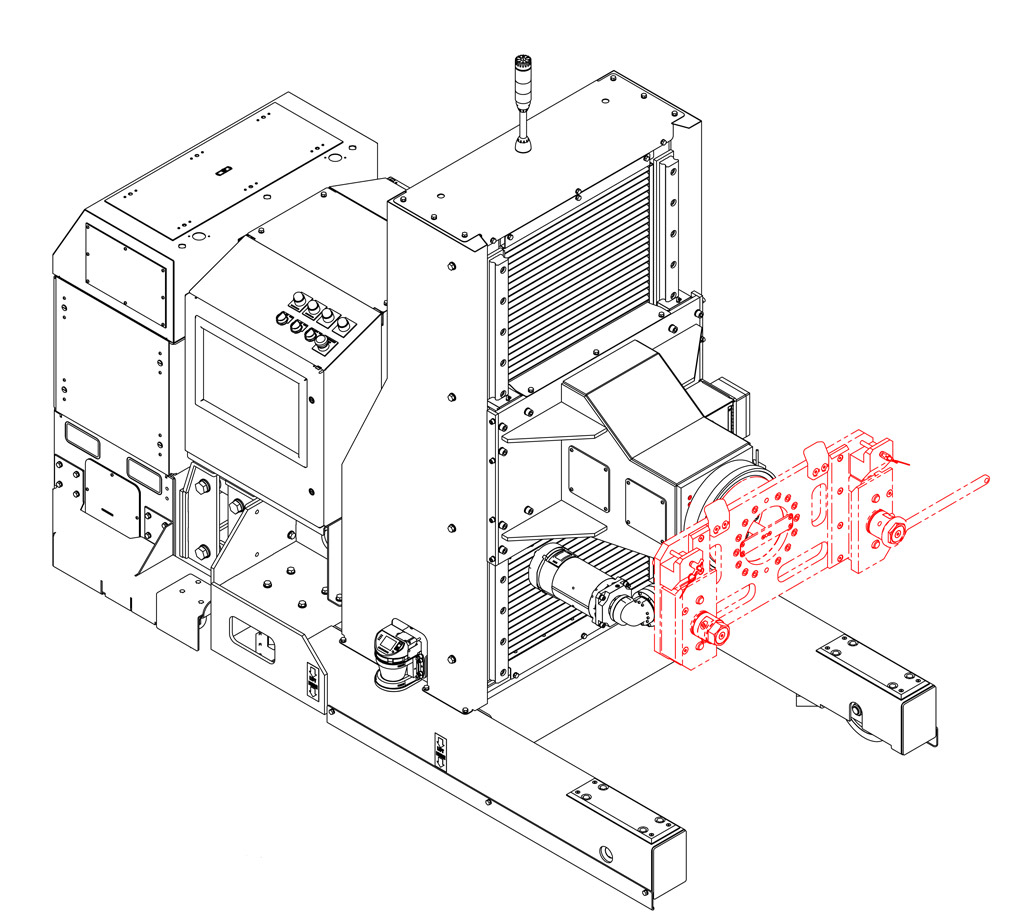

Automation Solutions of America (ASA), a subsidiary of The Morse Group, worked with Mercury Marine to develop an Automatic Guided Vehicle (AGV) solution for their V12 Verado engine assembly line. The project needed to be affordable, user friendly, flexible, and had to incorporate their already proven AGV system. Over the course of 14 months, the team developed, refined, and finalized an AGV design that met Mercury’s needs and seamlessly incorporated it into their existing manufacturing process.

Project Description:

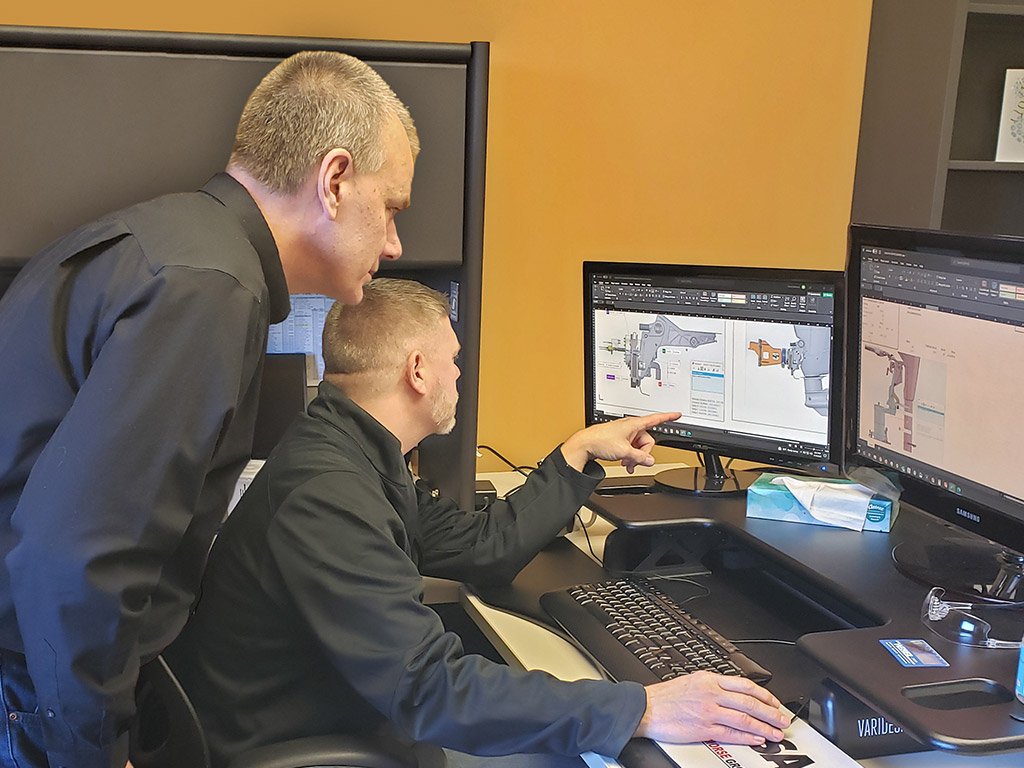

The first phase of this project involved clearly defining the objectives, creating initial concepts, and completing several rounds of revisions to reach an approved final design. During this phase of the project there was significant collaboration between ASA and the owner of Mercury Marine to ensure the concept took existing assembly processes into consideration and stayed on track to meet their needs. With the AGV design complete, the ASA team turned their attention to the manufacturing process. They developed a 22-station assembly line that guides the AGVs from start to finish utilizing flexible magnetic tape applied to the floor. The team programmed start and stop logic so AGVs could advance independently of one another without incident. To maintain the AGVs power supply, we strategically placed battery charging stations along the assembly line. The AGVs pass over the stations and make connection to charge their batteries periodically throughout the manufacturing process.